A paradigm shift in yachting: Diana Yacht Design and the 33m superyacht Lady Fleur

Written by: Alexander Griffiths

Publication: SuperyachtTimes

Changes in yachting are notoriously glacial – until last year. When Holterman Shipyard delivered its 32.65-metre superyacht X-treme 105, Lady Fleur, it was quite literally the ‘talk of the town’, and when she debuted at Cannes Yachting Festival the quay was awash with amazement.

Lady Fleur is radically practical and it’s easy to pass her off as a traditional monohull with a large aft deck for tender storage; but behind her taut muscular design is an unusual and complex piece of engineering: a novel aft deck that can be hydraulically lowered below the waterline to safely launch and retrieve a large tender.

The seed of inspiration was sown by her owners, who wanted a multipurpose aft deck: tender storage, a deep but safe swimming pool for their grandchildren, and somewhere to host intimate dinner parties. This all had to be squeezed into a 32.65-metre platform. Bernd Weel Design was the studio behind stylish, muscular and very attractive exterior design. But the big question, though: will it work? And who better to put the challenge to than Diana Yacht Design?

“We’re not afraid of a challenge,” Casper Marelis, Naval Architect & Designer at Diana Yacht Design, told SuperYacht Times. “But this really was a major one, and we’ve definitely learnt a lot from this project.” The biggest learning curve, not only for DIANA but for the industry, was engineering a system that could deploy and retrieve a large tender, without the use of a crane. It was a major undertaking – and one that has never been done before. It also came with an added benefit: ease of boarding for both crew and guests.

Lady Fleur features a traditional motor yacht hull, but from amidships, her long aft is divided between two hulls, with the central divide making space for the tender lift that includes a lengthy pool. The platform can be lowered, in between the two hulls collecting seawater and then raised again, to create a pool. The maximum depth of the pool is 6-foot but it can be completely customised for when the younger members of the family are enjoying a swim. When underway the pool floor is hydraulically lifted, turning the aft deck into a wide, flat multi-functional space.

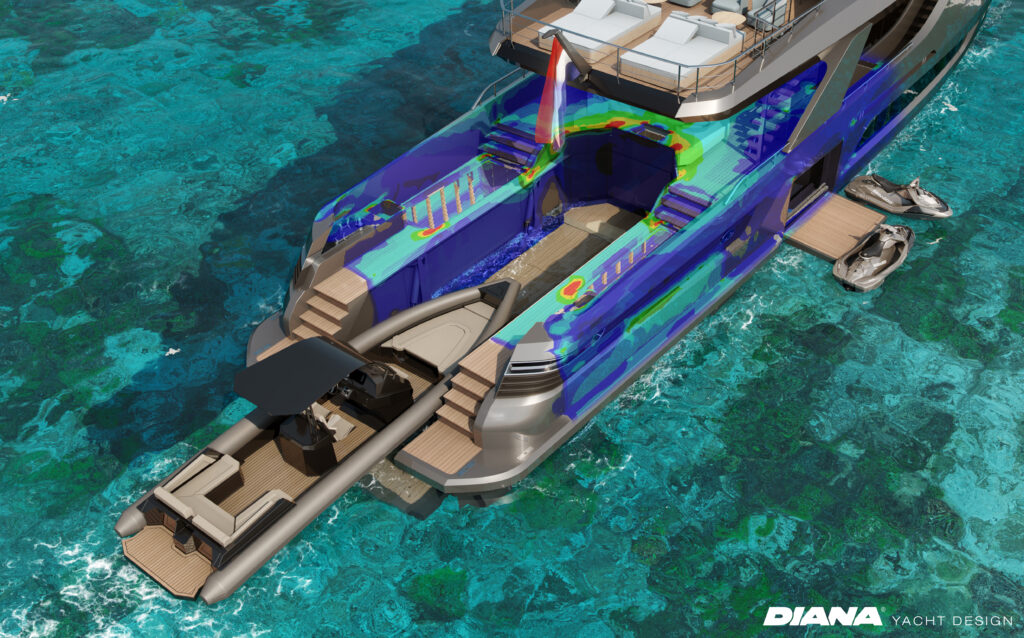

“Compared to a ‘normal’ catamaran hull the deck above/between the two hulls on Lady Fleur which normally absorbs the forces created by waves is missing,” Marelis explained. “So this means theoretically the PS hull can move up and the SB hull can move down. These forces all transfer to the connection point to the monohull instead of the deck above. An extensive ‘Finite Elements Method’ short FEM calculation made it possible to analyse these forces and the resulting tensions in the structure and made it possible to strengthen the problem areas very precisely. To give you an example, there are parts which had to be 40mm thick high tensile steel while without the fold down platform the thickness could be 5mm normal steel.”

Diana Yacht Design conducted rigorous FEM analysis of the total hull construction very early on in the process, and in direct conversation with classification society and flag state. Even though this was novel, the studio was determined to actualise the owner’s wishes. Coincidently, after devising a method for the system to raise and lower, the pool was relatively easy to engineer.

“The forces on the system depend on how much of a closed volume (air) must be pushed underwater. So we made the structure of the platform hollow above the waterline to minimise this volume. This left a big ‘empty space’ which could also house a pool. This can fill up while the system lowers. And although almost 14 tonnes of water has to be lifted afterwards, the closed volume of the platform will push this extra weight upwards.”

Naturally though, such a radical design was to cause waves throughout the vessel and more challenges arose, especially after a last-minute request to add a garage at midships: where to place the engine room?

“With the last minute change it meant that all the equipment moved aft, but also the structural parts like the engine seating. This meant a lot of extra weight in the aft ship for which the hull form had to be adapted. More weight in the multihull arms also meant more forces and vibrations which had to be accounted for,” Marelis said. “Due to the addition of a tender garage the multihull arms turned into the engine rooms. This meant splitting the engine rooms, so doubling up on multiple systems while the space got smaller. But this also meant moving the propshafts outboard which has a negative effect on flow towards the propeller. To have a proper water flow towards the propellers steering nozzles were added.”

The FEM calculation was an integral part of the aft section of Lady Fleur, but for the forward section was treated as normal. This helps reduce lead time as it “made it possible to start building the forward section already while a lot more engineering time was created to be spent on the difficult aft ship section.”

But the aft deck is just one part of the story. Lady Fleur also has a large enclosed tender garage, accommodation for 10 guests, and a dedicated crew apartment – all within a 200 GT package.

Lady Fleur truly defies the impossible, and when pressed if DIANA is looking at other ways to revolutionise yacht design, Marelis said: “We are up to the challenge for sure, we try to implement new ideas in our own concepts like Kaizen and Blue Angel for instance. But if an owner or shipyard has some wild idea like with Lady Fleur, we are open to investigate and hopefully realise it.”