Construction

Naval architecture brings together exterior yacht design, hull form development and engineering to create a realisable design – and this is where construction comes in.

At Diana Yacht Design, our multi-skilled construction team of naval architects and engineers are on hand to help you navigate the complexities of building a yacht.

Naval architecture brings together exterior yacht design, hull form development and engineering to create a realisable design – and this is where construction comes in.

At Diana Yacht Design, our multi-skilled construction team of naval architects and engineers are on hand to help you navigate the complexities of building a yacht.

The backbone of your yacht

The preparation of construction drawings and calculations is a vital part of the design process, serving as the blueprint for a safe and seaworthy yacht. Whether it’s steel, aluminium or wood, Diana Yacht Design has the wide-ranging experience to cover all bases.

Our engineers begin with the scantling calculations at an early stage, ensuring that all Lloyds/RINA/BV regulations and requirements are met. This initial information gathering helps the naval architect to determine the weight and height of the structure. The later stage of the process involves creating detailed drawings, including shell expansion drawings, which provide the shipyard with all the necessary information it needs to build the yacht in the most cost-effective way possible.

Unrivalled design support

Each one of our individual in-house specialists is assigned a specific part of the yacht which they have direct responsibility for checking. This ensures that our clients enjoy the most comprehensive design support possible.

Designed by experts

At Diana Yacht Design, we don’t like to wait on the sidelines. Our representatives attend design meetings with the shipyard and their partners – this enables us to make the most of all of the available synergies, building on the expertise of all parties involved.

On-site building supervision

We are proud to offer comprehensive on-site supervision for the whole build process. This ensures that the integrity of the vessel’s design is maintained throughout, as well as making sure that the levels of finish, sophistication and craftsmanship correspond to our exacting standards.

Always planning ahead

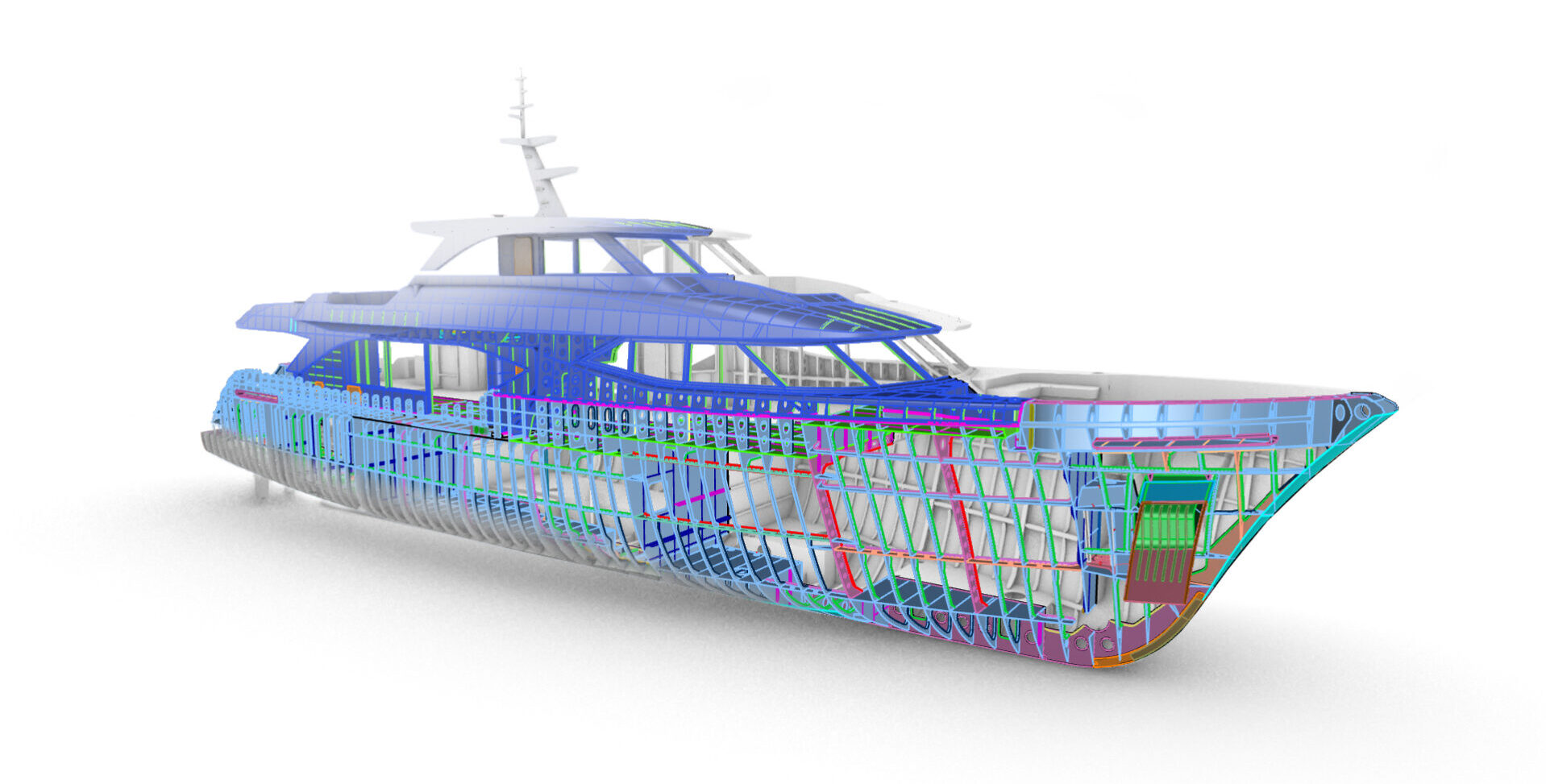

In the early stages of a project, we start with a 2D CAD drawing of the general construction plans for both the hull and superstructure. This allows us to get the plans to the relevant class society as efficiently as possible, without the need for a production-ready 3D service model.

We also base our preliminary weight calculations on these early drawings to get a feel for the speed, range and stability of the vessel.

Attention to detail

Once the class society signs off on our 2D CAD drawings, and a detailed 3D model has been constructed, we begin making detailed section drawings. These drawings will eventually end up in the hands of the craftspeople at the shipyard – so we spend a lot of effort in making sure that every detail is perfect.

Based on these drawings, our team of specialists then creates the construction in 3D so that cutting accurate files and building frames can be formulated.

A tried and tested method

We have been using this workflow for a long time at Diana Yacht Design, and with good reason: it works. Using 2D drawings in the early stages allows us to work more efficiently and make changes easily. As a result, there are no surprises once the time comes to make the cutting files, and construction can proceed without a hitch. What could be easier?